Product Video

Material Picture Display

Advantages

Datu Technology's vibrating knife cutting machine has a comprehensive cutting plan for carpets, including cutting of natural fibers, chemical fibers and blended materials. In the ever-increasing variety of commodities, floor coverings can be produced individually, with high-precision and automated production methods, and with short production cycles. It uses the most advanced technology and the highest quality components. The flexibility, reliability and quality of Datu Technology's vibrating knive cutting machine is much better than other machining.

Export Packaging Display

After-sales Service

(1) One-year warranty policy. (2) 7*24-hour online service. (3) Provide lifetime free technology upgrade service. (4) Free training in our factory, if time is not convenient, we can also provide complete training video. (5) On-site technical support can be provided by negotiation.Parameter Table

| Equipment Model | DT-2516A |

| Scope Of Work | 2500x1600mm |

| Drive System | Imported Mitsubishi Servo Motor Drive |

| Transmission System | Pmi Linear Guide Rail, Precision Rack Drive |

| Maximum Cutting Speed | 1800mm/s |

| Cutting Material | Silk, Cotton,Viscose Staple Fiber, Nylon Bcf Filament Etc. |

| Cutting Tools | Vibrating Knife, Round Knife Etc. |

| Cutting Thickness | 0.1-30mm (Subject To Specific Materials) |

| Cutting Accuracy | ±0.01mm |

| Repetition Accuracy | ±0.03mm |

| Feeding Method | Automatic Feeding |

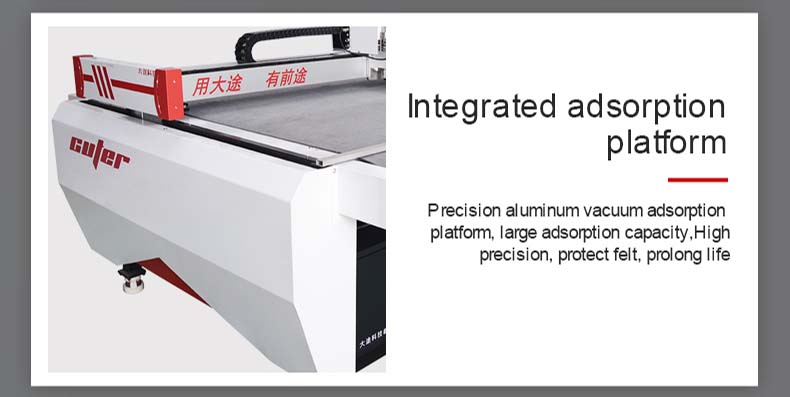

| Fixing Method | All Aluminum Table Vacuum Adsorption |

| Transmission Interface | Usb/u Disk/Network |

| Power Supply And Power Of Cutting Equipment | 220v/50hz 2.5kw |

| Power Supply And Power Of Vacuum Pump | 380v 7.5kw/9kw (Optional) |

| Positioning Method | Infrared Laser, Ccd Camera (Optional) |

| Safety Device | Infrared Laser Induction, Safe And Stable |

| Pneumatic Fittings | Festo, Germany/Yadek, Taiwan |

| Electrical Fittings | Chint/Delixi |

Cutting Result Picture

1. There are more cutting configurations for round cutter, vibrating cutter and pneumatic cutter.

2. 1800MM/S high speed, the precision of repeated positioning to the cutting origin is ±0.01mm.

3. Mitsubishi servo motors, Taiwan Hindwin guide rails and other brand electrical components, double rack machines are more durable

4. Equipped with a large visual intelligent edge inspection system, cutting and proofing are faster.

5. One-click import of drawings, convenient for cutting, data import and direct cutting, no paper version is required. save time.

6. Support for multiple file formats (AI, PLT, DXF, CDR, etc.), making it more convenient to use and interact.

7. The cutting section is clean and smooth, without chips and burrs 8. Edge cutting can be performed according to the printing requirements of raw materials Applicable tools: vibrating kinfe, round knife Applicable models: DT-2516AHardware Display

Product Introduction

Standard carpet fiber raw materials are natural fibers, chemical fibers, and blends. Among them, natural fibers include wool, silk, cotton, jute, etc.; chemical fibers include viscose staple fiber, nylon BCF filament, and staple fiber, acrylic staple fiber, polypropylene BCF filament and staple fiber, and polyester staple fiber; blended with wool/nylon, wool/viscose, wool/acrylic, wool/polyester, and wool/jute. They are the typical soft materials. To achieve industrial upgrading and improve production efficiency and capacity, advanced cutting equipment has become the general trend. The vibrating knife cutting machine is a relatively widely used processing equipment in the flexible material cutting process. It uses the upper and lower high-frequency vibration of the blade to cut. It has high precision, fast cutting speed, and is not limited by the cutting pattern. It can be automatically loaded and unloaded. Intelligent typesetting, smooth incision, low processing cost and other characteristics, gradually improve or replace the traditional flexible cutting process equipment.