As a global manufacturer of CNC cutting equipment, Shandong Datu Intelligent Technology Co., Ltd. has established itself as a leader in providing industry solutions for intelligent cutting of non-metallic materials. Based in Jinan, the company has continuously pushed the boundaries of technological innovation to meet the ever-evolving needs of the manufacturing sector.

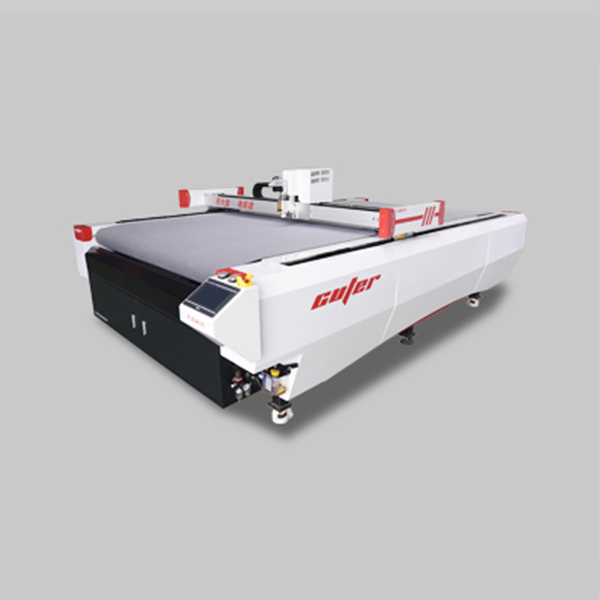

The Automated Cutting System for Car Interior Fabrics is the latest addition to the company's impressive portfolio of cutting-edge products. This system is designed to automate the cutting process for car interior fabrics, including upholstery, carpets, and other non-metallic materials. By leveraging advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), the system offers unparalleled precision and speed, allowing car manufacturers to significantly reduce production time and costs.

One of the key features of the Automated Cutting System is its ability to handle a wide range of materials with varying thickness and density. This versatility makes it an ideal solution for car manufacturers who produce a diverse range of vehicle models with different interior design specifications. Whether it's a luxury sedan with premium leather upholstery or a compact hatchback with durable fabric seats, the system can effortlessly accommodate the unique requirements of each car interior.

Furthermore, the Automated Cutting System is equipped with intelligent software that can optimize material usage, minimize waste, and maximize yield. This not only contributes to cost savings but also aligns with the growing emphasis on sustainability within the automotive industry. By reducing material wastage, car manufacturers can minimize their environmental footprint and contribute to a more eco-friendly production process.

The introduction of the Automated Cutting System is poised to revolutionize the way car interior fabrics are manufactured. With its ability to automate complex cutting patterns and intricate designs, the system empowers car manufacturers to bring their creative visions to life with unparalleled precision and efficiency. This, in turn, enables them to deliver high-quality, customized car interiors that meet the demands of today's discerning consumers.

In addition to its cutting-edge technological capabilities, the Automated Cutting System is backed by Shandong Datu Intelligent Technology Co., Ltd.'s commitment to exceptional service and support. The company offers comprehensive training and ongoing technical assistance to ensure that its customers can fully harness the potential of the system. This dedication to customer satisfaction has positioned Shandong Datu Intelligent Technology Co., Ltd. as a trusted partner for car manufacturers seeking to optimize their production processes.

The impact of the Automated Cutting System for Car Interior Fabrics extends beyond the automotive industry. Its potential to enhance efficiency and precision in cutting non-metallic materials has far-reaching implications across various sectors, including furniture manufacturing, apparel production, and more. By leveraging the advanced technology developed by Shandong Datu Intelligent Technology Co., Ltd., manufacturers in these industries can unlock new possibilities for innovation and productivity.

In conclusion, Shandong Datu Intelligent Technology Co., Ltd.'s Automated Cutting System for Car Interior Fabrics represents a significant leap forward in the field of intelligent cutting technology. With its cutting-edge capabilities, versatility, and commitment to customer satisfaction, the system is set to redefine the manufacturing processes for car interior fabrics and beyond. As the automotive industry continues to evolve, this innovative solution is poised to play a pivotal role in driving efficiency, quality, and sustainability for car manufacturers worldwide.